Have you ever wondered how early explorers managed to survive in the wilderness for extended periods, or how some communities still thrive in remote, water-scarce regions? The answer lies in a simple yet ingenious technology: the survival still. This versatile device, a masterclass in distillation, serves a dual purpose

- water purification and alcohol fuel production. In this comprehensive guide, we delve into the art and science of building a survival still, empowering you with the knowledge to ensure your safety and sustainability in challenging environments.

First, let’s address the elephant in the room. Water is the elixir of life, and access to clean, potable water is a global challenge. According to the World Health Organization, around 2.2 billion people lack access to safely managed drinking water. A survival still can significantly alleviate this issue, making it an invaluable tool for both emergency preparedness and off-grid living.

Now, you might be wondering, ‘Why alcohol fuel?’ Well, alcohol, specifically ethanol, is a clean-burning fuel that can power various devices, from lanterns to generators. It’s renewable, as it can be produced from a wide range of plant materials, and it significantly reduces greenhouse gas emissions compared to fossil fuels. Moreover, in a survival situation, alcohol can also serve as a disinfectant and a base for homemade medicines.

In this article, we promise to demystify the process of building and operating a survival still. We’ll explore the science behind distillation, guide you through the construction process using readily available materials, and provide tips on optimizing your still’s performance. By the end of this read, you’ll not only understand how to purify water and produce fuel but also gain insights into the fascinating history and applications of distillation.

So, whether you’re an avid camper looking to lighten your load, a prepper aiming to enhance your emergency kit, or simply a curious mind eager to learn a new skill, this article is for you. Let’s embark on this journey of discovery, where we’ll transform simple ingredients into life-saving essentials, one drop at a time.

Mastering Distillation for Off-Grid Living

Embarking on a journey towards self-sufficiency, one might find themselves captivated by the art of distillation. This ancient practice, once reserved for alchemists and monks, is now a vital skill for those seeking off-grid living. Distillation, at its core, is a process of separation, harnessing the power of heat and cold to divide liquids into their constituent parts. It’s a dance of elements, a symphony of science and art, transforming simple ingredients into elixirs of extraordinary value. In the context of off-grid living, distillation becomes a lifeline, enabling the conversion of rainwater into drinkable water, or transforming excess fruit into a sweet, preservative-free nectar. It’s a means to create alcohol for fuel, or essential oils for medicine and fragrance. Mastering distillation is not just about acquiring a new skill; it’s about embracing a new way of life, one that honors the cycles of nature and the power of human ingenuity. It’s about understanding that in every drop, there’s a story of transformation, a testament to our ability to adapt and thrive in harmony with our environment.

Understanding Distillation

Distillation, a process as old as civilization itself, is a cornerstone of human survival and innovation. Its roots can be traced back to ancient times, with evidence of its use dating back to the ancient Greeks and Romans. They employed it primarily for creating perfumes and essential oils, but its true significance lies in its ability to purify water and produce alcohol fuel, a lifeline in survival situations.

The principle of distillation is based on the unique properties of different substances, particularly their boiling points. Water, for instance, boils at 100°C (212°F) at standard atmospheric pressure, while impurities like salt, minerals, and bacteria have much higher boiling points. Alcohol, on the other hand, boils at a lower temperature, around 78.4°C (173.1°F).

In water distillation, the process begins with heating water. As it reaches its boiling point, it turns into steam, leaving behind impurities. This steam is then cooled and condensed back into liquid water, resulting in pure, drinkable water. This method is crucial in survival situations where water sources may be contaminated.

In alcohol production, the process is similar but starts with a mixture of water and fermented sugars. As the mixture heats, the alcohol vaporizes first due to its lower boiling point. This vapor is then collected and cooled, yielding a concentrated solution of alcohol, or ethanol. This process is not only vital for creating beverages but also for producing biofuels, a renewable energy source.

Understanding and mastering distillation is not just about survival; it’s about harnessing the power of nature’s elements to create life-sustaining resources. It’s a testament to human ingenuity, a skill that has evolved over centuries, and a practice that continues to shape our world today.

Gathering and Preparing Materials

Building a survival still, an essential tool for water purification in off-grid situations, requires careful gathering and preparation of materials. The primary component is a heat-resistant container, such as a large glass jar or a stainless steel pot, which can be sourced from thrift stores, garage sales, or even recycled from your kitchen. A tight-fitting lid is also crucial, as it will house the condenser tube. This can be fashioned from a piece of copper tubing, available at hardware stores, or repurposed from an old refrigerator coil. A large piece of cloth, like an old t-shirt or sheet, is needed for creating a wick to draw water up the condenser tube. A heat source, such as a campfire or a portable stove, is necessary to boil the water. Additionally, you’ll need tools like a drill, a hammer, and some nails or screws to assemble the still.

To prepare the materials, first, clean and sterilize the container and lid to ensure no contaminants remain. The copper tubing should be cut to a length that allows it to reach from the bottom of the container to the top of the lid, with a few inches extending out. Drill a hole in the lid to fit the tubing snugly. For the wick, cut the cloth into a long, thin strip, wide enough to fit inside the tubing. Once all materials are prepared, you’re ready to assemble your survival still, a vital piece of equipment for ensuring a clean water supply in survival situations.

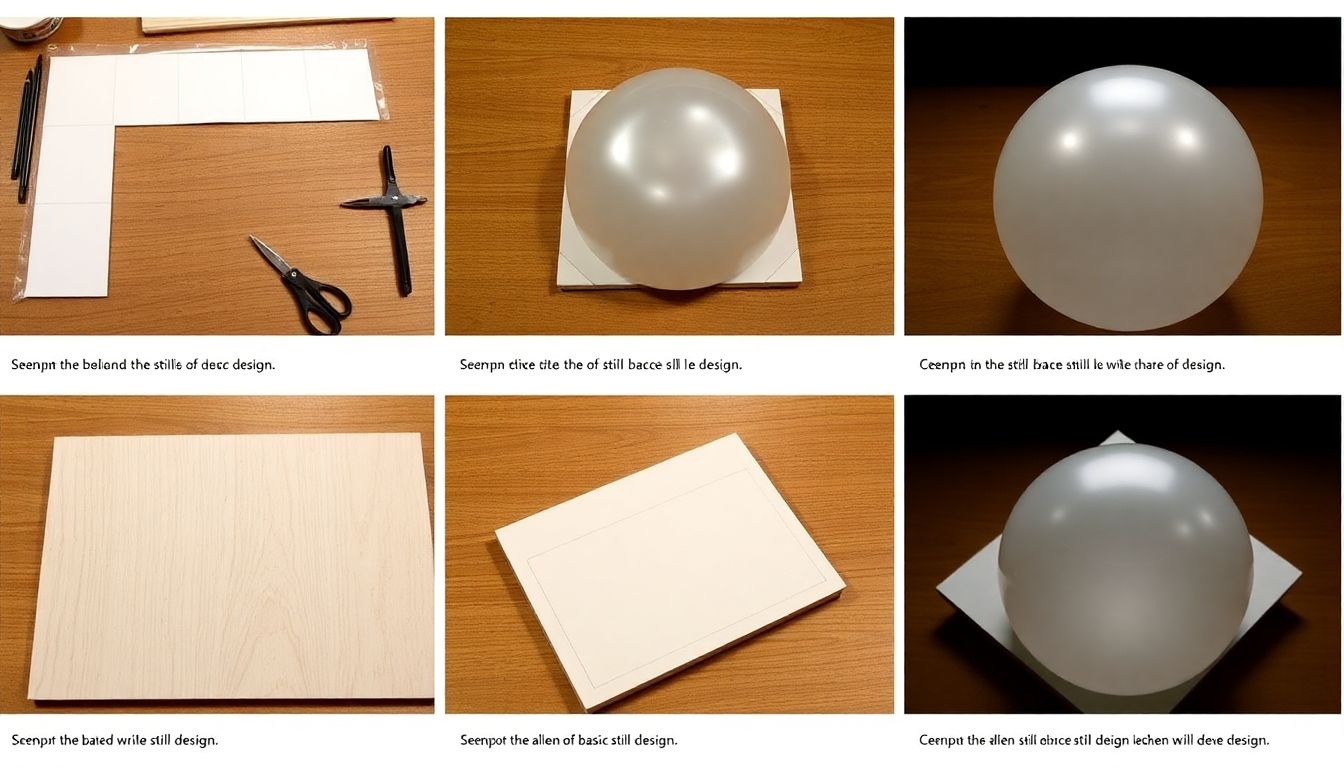

Assembling the Still: The Basic Design

Assembling a basic still design is an intriguing process that combines science, art, and a touch of history. Let’s embark on a step-by-step journey to create this fascinating piece of apparatus, which has been used for centuries to distill a variety of liquids, from water to spirits. Remember, safety is paramount when handling heat and flammable liquids, so always ensure you’re working in a well-ventilated area and never leave your still unattended while in use.

The basic still design consists of four main components: the boiler, the condenser, the receiver, and the tubing that connects them. Let’s start with the boiler, the heart of our still. It’s a simple vessel where our liquid will be heated and vaporized. You can use a large glass flask or a stainless steel pot for this purpose. Ensure it’s clean and dry before starting.

Next, we’ll need a condenser. This is where the vaporized liquid will cool down and condense back into a liquid state. A simple glass tube wrapped in a coil and submerged in cold water works perfectly for this. Make sure the tube is long enough to allow for sufficient cooling.

Now, let’s connect our boiler and condenser. We’ll need a length of tubing, preferably made of copper or stainless steel, for this. One end will be inserted into the boiler, just above the liquid line, to draw out the vapor. The other end will be inserted into the condenser, ensuring it’s fully submerged in the cooling water.

Our final component is the receiver. This is where our condensed liquid will drip into. It can be a simple glass jar or a bottle. Make sure it’s clean and dry, and place it below the condenser to allow for gravity to do its work.

Now, let’s put it all together. Here are the steps:

- Secure the boiler on a sturdy stand or heat source.

- Connect the tubing to the boiler, ensuring it’s above the liquid line.

- Submerge the other end of the tubing in the condenser, ensuring it’s fully covered by the cooling water.

- Place the receiver below the condenser, allowing for gravity to drip the condensed liquid into it.

- Slowly heat the boiler, monitoring the process closely. As the liquid vaporizes, it will travel through the tubing, cool down in the condenser, and drip into the receiver.

And there you have it! Your basic still design is now assembled and ready for use. Whether you’re distilling water, essential oils, or creating your own spirits, this simple design will serve you well. Always remember to practice safe distilling techniques and enjoy the process of turning one liquid into another.

Improving Efficiency: Advanced Designs

In the pursuit of maximizing water production and efficiency, let’s delve into two advanced still designs: the fractionating column and the solar still.

The fractionating column is a sophisticated addition to the traditional still, designed to improve the purification process. It consists of multiple sections, each with a different temperature, allowing for a step-by-step distillation. This design offers several advantages. Firstly, it increases the purity of the final product by allowing water vapor to condense at different temperatures, leaving behind more impurities. Secondly, it can significantly reduce the energy required for distillation, as the heat from the condensing vapor in one section can be used to heat the liquid in the next section below, a process known as heat integration.

However, the fractionating column is not without its drawbacks. Its complex design makes it more expensive and difficult to construct and maintain compared to traditional stills. It also requires a larger surface area, which can be a limitation in space-constrained environments.

The solar still, on the other hand, harnesses the power of the sun to distill water, making it an eco-friendly and cost-effective option. It consists of a transparent cover, usually made of glass or plastic, which traps sunlight and heats the water inside. As the water heats up, it evaporates and condenses on the cooler underside of the cover, where it drips into a collection tray.

The solar still has several advantages. It’s simple to construct and maintain, and it’s powered by the sun, making it a sustainable and cost-effective solution. It also produces pure water, as the evaporation and condensation process leaves behind most impurities. However, its efficiency can be limited by factors such as cloud cover, temperature, and humidity, which can affect the rate of evaporation. It also requires a large surface area to collect a significant amount of water.

Water Treatment: Purifying Water with a Still

In the realm of water purification, the still is an ancient yet reliable tool that has stood the test of time. A still, essentially a simple distillation unit, can transform even the most contaminated water into a clean, drinkable liquid, making it an invaluable asset in survival situations. The process begins with collecting water from a potential source, which could be anything from a murky pond to rainwater harvested from a tarp. The water is then poured into the still’s container, typically a large glass or metal vessel.

The heart of the still is its design, which consists of a heat source, the container for the water, a condenser, and a collection vessel. The heat source, usually a fire or a heat-resistant stand, is placed beneath the container. As the water heats up, it begins to evaporate, leaving behind any impurities, including bacteria, viruses, salts, and heavy metals. The steam rises and comes into contact with the condenser, a cool surface, which causes the steam to condense back into liquid water. This purified water then drips into the collection vessel.

The output of this process is pure, drinkable water. However, it’s important to note that while a still can remove many impurities, it may not eliminate all types of contaminants. For instance, it might not effectively remove certain chemicals or viruses that have a low boiling point. Therefore, it’s crucial to use a still in conjunction with other water treatment methods, such as filtration and disinfection, for comprehensive purification.

Proper water treatment is not just a matter of convenience; it’s a matter of survival. In emergency situations, access to clean water can be limited, and drinking contaminated water can lead to severe dehydration, illness, or even death. A still provides a means to turn potentially harmful water into a life-saving resource. Moreover, it’s a tool that requires no electricity, no specialized knowledge, and can be constructed using simple, readily available materials. In a survival situation, these qualities make the still an indispensable piece of equipment.

Producing Alcohol Fuel: The Distillation Process

The art of producing alcohol fuel, or bioethanol, through distillation is a fascinating process that has been refined over centuries. The journey begins with selecting an appropriate feedstock, which can range from agricultural crops like corn or sugarcane to waste materials such as municipal solid waste or even algae. These feedstocks are first fermented with yeast to convert their sugars into a mixture of ethanol and water, known as ‘wash’ or ‘beer’.

The heart of the operation is the still, a vessel designed to heat the wash and capture the vapor that condenses back into liquid. There are several types of stills, from simple pot stills to complex column stills, each with its own efficiency and complexity. The process involves heating the wash gently, allowing the ethanol to vaporize at a lower temperature than water. As the vapor cools, it condenses back into liquid, and the ethanol, being more volatile, separates from the water.

The resulting liquid is a mixture of ethanol and water, known as ‘low wines’. This is then distilled again, often multiple times, to increase the ethanol concentration. The final product, known as ‘spirits’, can be up to 95% ethanol, ready for use as fuel.

However, handling alcohol fuel requires careful safety precautions. Ethanol is highly flammable, with a low flashpoint, making it a potential fire hazard. It’s crucial to avoid open flames and ensure proper ventilation. Additionally, ethanol can be harmful if ingested or inhaled, so protective clothing and safety equipment should be worn. Regular maintenance of the still is also essential to prevent leaks and ensure safe operation. Despite these precautions, producing alcohol fuel can be a rewarding process, turning waste materials into a clean, renewable source of energy.

Safety and Maintenance: Keeping Your Still in Top Shape

Operating a still, whether it’s for distilling water, essential oils, or spirits, requires a blend of precision, patience, and safety consciousness. Ensuring the longevity and efficiency of your still is a dance of regular maintenance and careful operation. Let’s dive into the safety measures and maintenance tips that will keep your still in top shape.

First and foremost, safety should always be your top priority. A well-ventilated workspace is not just a comfort, but a necessity. Stills produce vapor, and if not properly ventilated, this vapor can condense and create a slippery surface, leading to accidents. Moreover, proper ventilation helps prevent the buildup of flammable vapors, which can pose a significant fire risk. Always ensure your still is in a well-ventilated area, preferably with an exhaust fan.

Handling hot components is another crucial aspect of safe still operation. Stills can reach high temperatures, and touching these components without proper protection can result in severe burns. Always use heat-resistant gloves and ensure that the still has cooled down significantly before attempting to clean or move it. It’s also a good idea to keep a fire extinguisher nearby, just in case.

Preventing explosions is another critical safety measure. Never leave your still unattended while in operation. Sudden changes in temperature or pressure can cause explosions. Regularly check your still’s pressure gauge and ensure it’s within the safe operating range. If you notice any unusual behavior, such as excessive pressure buildup or strange noises, shut down the still immediately.

Now, let’s talk about maintaining your still. Regular cleaning is key to ensuring its longevity and efficiency. After each use, disassemble the still and clean each component thoroughly. Use a mild detergent and warm water, avoiding harsh chemicals that could damage the still. Pay special attention to the condenser, as any buildup of residue can reduce its efficiency.

Another important aspect of maintenance is checking for leaks. A leaky still can lead to inefficient operation and potential safety hazards. Inspect your still regularly for any signs of leaks, and repair them promptly. Additionally, ensure that all seals and gaskets are in good condition and replace them as needed.

Lastly, always follow the manufacturer’s guidelines for your specific still. Each still is unique, and understanding its specific needs and limitations is crucial for safe and efficient operation.

Troubleshooting Common Issues

When it comes to distilling spirits, even the most seasoned enthusiasts can encounter common issues that may hinder the process or affect the final product. Let’s delve into three such issues and explore their solutions and preventive measures.

Low Alcohol Yield:

- This issue often stems from using a mash with a low sugar content or an inefficient fermentation process. To troubleshoot, ensure your mash contains enough sugar by using a reliable recipe and ingredients. Additionally, monitor your fermentation temperature; ideally, it should be between 70-75°F (21-24°C) for optimal yeast activity. If the yield is still low, consider repitching your yeast or using a yeast nutrient to boost fermentation.

Preventive Measures:

- Always use fresh, high-quality ingredients and maintain optimal fermentation conditions.

Solution:

Monitor and adjust fermentation temperature, repitch yeast if necessary, or use yeast nutrient.

Slow Distillation Rate:

- A slow distillation rate can be caused by a clogged still, insufficient heat, or a poorly sealed system. To address this, first, ensure your still is clean and free of any residue that could clog the system. Next, check your heat source; it should be providing consistent and adequate heat. Lastly, ensure your still is properly sealed to maintain pressure and distillation rate.

Preventive Measures:

- Regularly clean your still, maintain your heat source, and ensure a proper seal.

Solution:

Clean your still, check and maintain heat source, and ensure a proper seal.

Improperly Purified Water:

- Using improperly purified water can lead to off-flavors in your final spirit. This issue can be resolved by using a high-quality water filter or distilling your water to remove impurities. Always remember that the water used in your mash can significantly impact the final product.

Preventive Measures:

- Use a high-quality water filter or distill your water.

Solution:

Use a high-quality water filter or distill your water.

Creative Uses for Your Survival Still

Beyond its life-saving purpose, a survival still, with its ability to distill liquids, opens up a world of creative possibilities. One such avenue is the extraction of essential oils from plants. To create your own, start by crushing or grinding the plant material, then place it in a cloth bag. Hang this bag in the still’s boiler, ensuring it’s fully submerged in water. As the water heats up and turns to steam, it will carry the essential oils from the plant through the still’s coil and into the collection vessel. This process can be used to create oils from a variety of plants, from lavender to eucalyptus, each with its own unique scent and potential health benefits.

Another fascinating use of a survival still is in the art of perfumery. By distilling different flowers, woods, or resins, you can create your own unique fragrances. To make a simple perfume, start by collecting and preparing your chosen ingredients. Distill them in the still, collecting the resulting oils. Once cooled, mix these oils in a small bottle, adding a carrier oil like jojoba or almond oil to dilute the fragrance. Allow the perfume to age for a few weeks, shaking it occasionally to help the scents meld together.

But the creative uses don’t stop at aromatherapy. With a few additional ingredients, your survival still can also produce delightful homemade liqueurs. For a simple lemon liqueur, peel the zest from several lemons, being careful not to include any of the bitter white pith. Place the zest in the still’s boiler, cover it with sugar and water, and distill. Once collected, mix the resulting liquid with vodka and let it age for a few weeks. The result is a tangy, homemade limoncello. Similarly, you can create other liqueurs by distilling different fruits, spices, or herbs, and combining the results with your spirit of choice.

So, while a survival still is an invaluable tool for emergency situations, it’s also a gateway to a world of creativity and experimentation. Whether you’re crafting your own essential oils, blending unique perfumes, or concocting homemade liqueurs, the possibilities are as endless as your imagination.

FAQ

What is the primary purpose of a survival still?

How does distillation purify water?

What kind of still is best for water purification?

Can a survival still also produce alcohol fuel?

What is the difference between a pot still and a reflux still?

What is the optimal temperature for distilling alcohol?

How can I make my still more efficient?

- Use a heat source that allows for precise temperature control, like an electric heating mantle or a propane burner.

- Insulate your still to retain heat and reduce energy loss.

- Use a reflux still design for better alcohol separation.

- Regularly clean your still to prevent the buildup of residue that can affect efficiency.

What safety precautions should I take when operating a still?

- Never leave the still unattended while in operation.

- Ensure proper ventilation to avoid the buildup of flammable alcohol vapors.

- Keep a fire extinguisher nearby.

- Wear heat-resistant gloves and safety glasses when handling hot components.

- Store your still and fuel safely, away from heat sources and potential ignition points.

What can I use as a fuel source for my still?

How can I maintain the longevity of my still?

- Regularly clean your still to remove residue and prevent corrosion.

- Inspect your still for any signs of damage or wear, and repair or replace components as needed.

- Store your still properly when not in use, protecting it from extreme temperatures and moisture.

- Use appropriate materials and techniques during construction to ensure durability.